The project I’m working on focuses on electrolysis of water namely making electrolysis cells for steam electrolysis. Water electrolysis (the splitting of water into oxygen and hydrogen using electricity) is an important process as hydrogen is a coveted material used in many industrial processes and it is believed it will play an important part in our society’s move to a cleaner energy system as it can be used to store energy. Electricity from e.g. windmills can be converted into hydrogen by electrolysis and can thus be stored.

Water electrolysis is most often done at relatively low temperature (less than 100 °C) but this requires expensive catalytically active materials and the liquid water can be somewhat of a challenge to handle. The idea with this project is to raise the temperature to between 200 and 400 °C and making it possible to use inexpensive electrocatalysts as well as feeding the cell with steam which easier to handle. This will make it cheaper to make hydrogen and it may be combined with different processes where heat is created as a by product.

My work revolves around collecting materials for the different parts of the electrolysis cells (e.g. the electrodes, the electrolyte and the gas diffusion layers) and fashioning functional cells from then. I then evaluate the cells as a whole and the different components individually on their performance during electrolysis of steam.

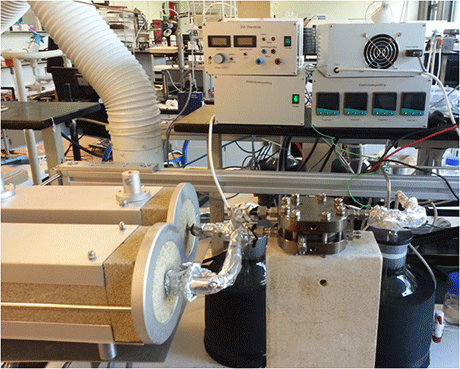

Figurtekst: A steam electrolysis setup for testing cells at tempetatures above 200 °C

The project is part of the MedLys project, funded by The Danish Council for Strategic Research.